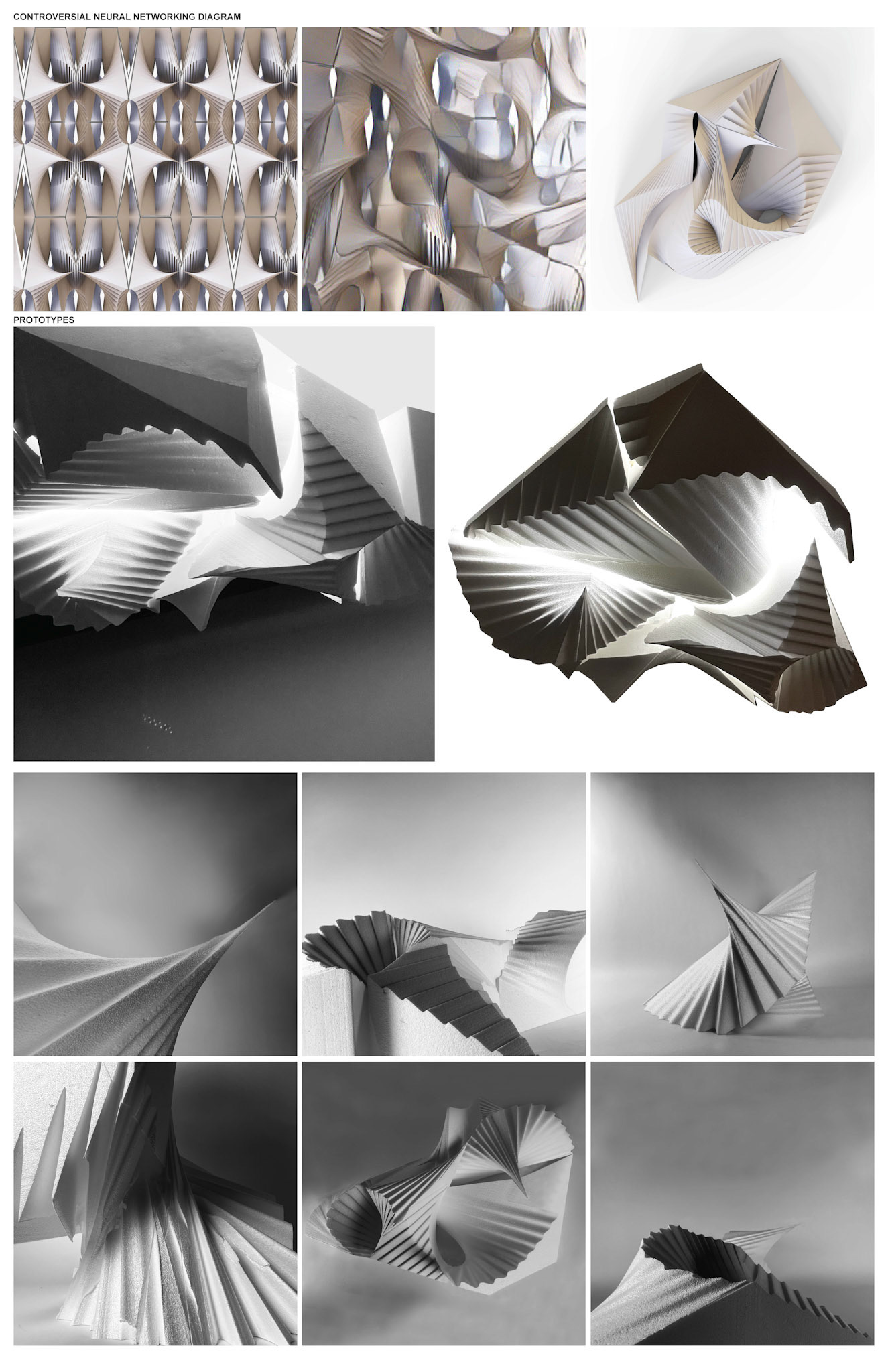

Prototypes

Concept

Naum Gabo’s Torsion variation number 3 was constructed using two warped metal frames. One emulated, mirrored and displaced perpendicular to the other. The edges of the frames act as the rails of the sculpture. It creates the outlines of where the strings begin to connect from point to point, creating the ruled surfaces.

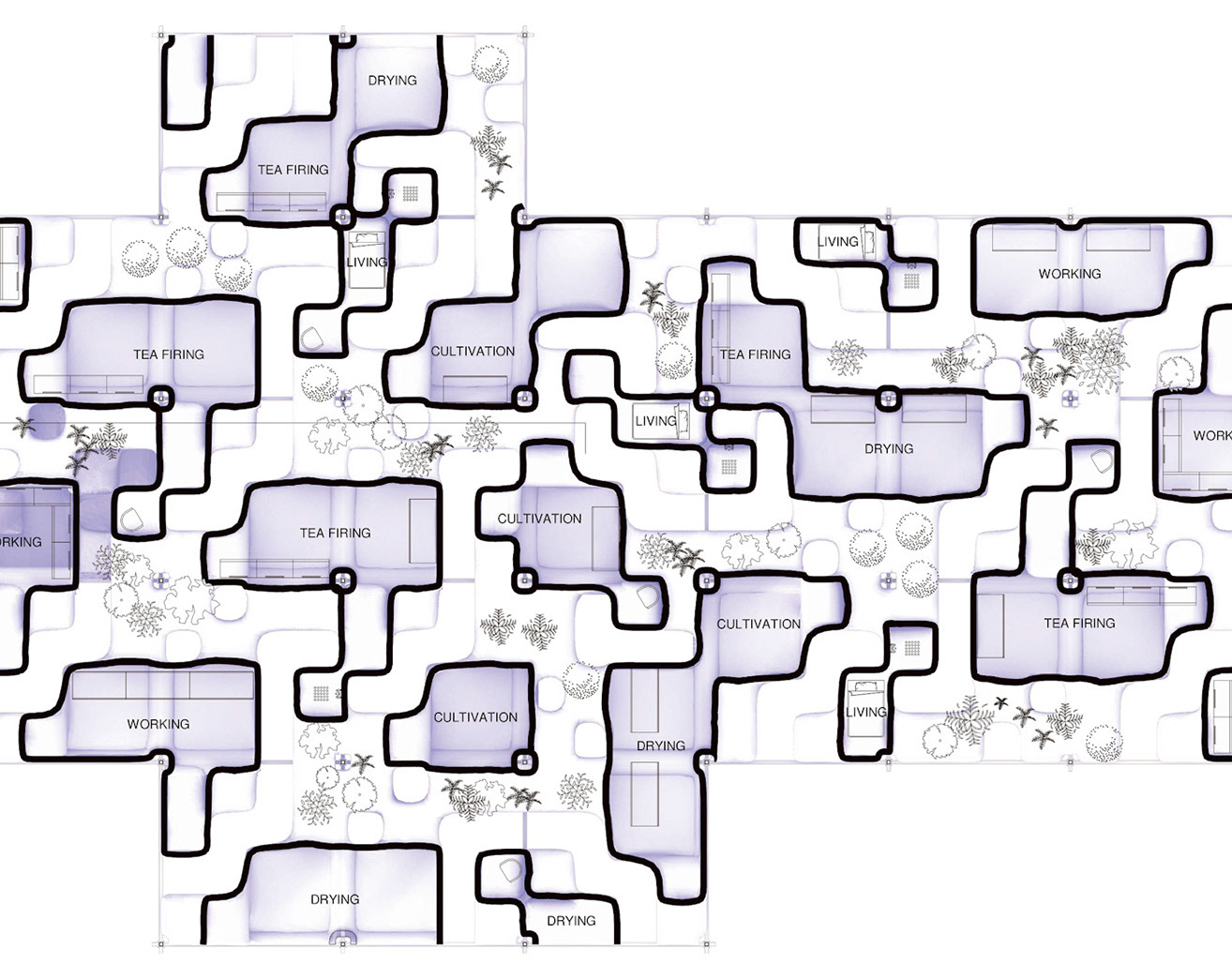

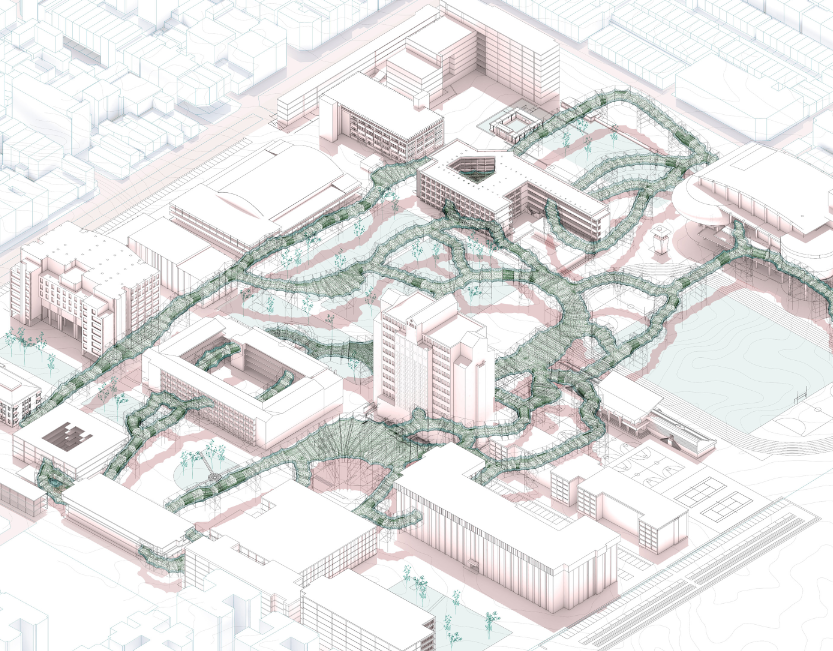

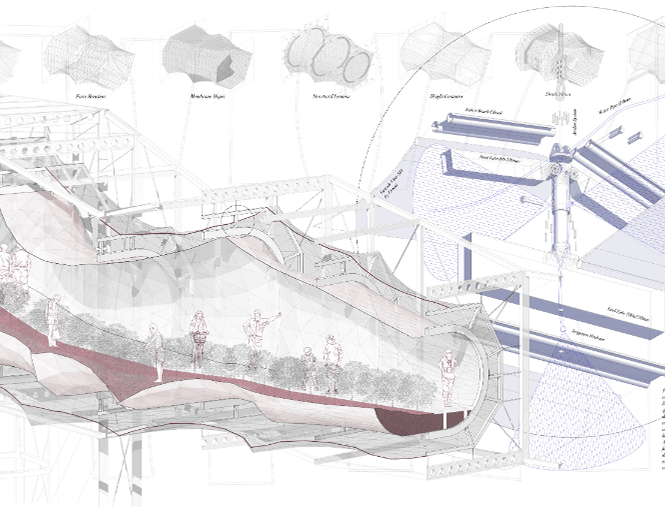

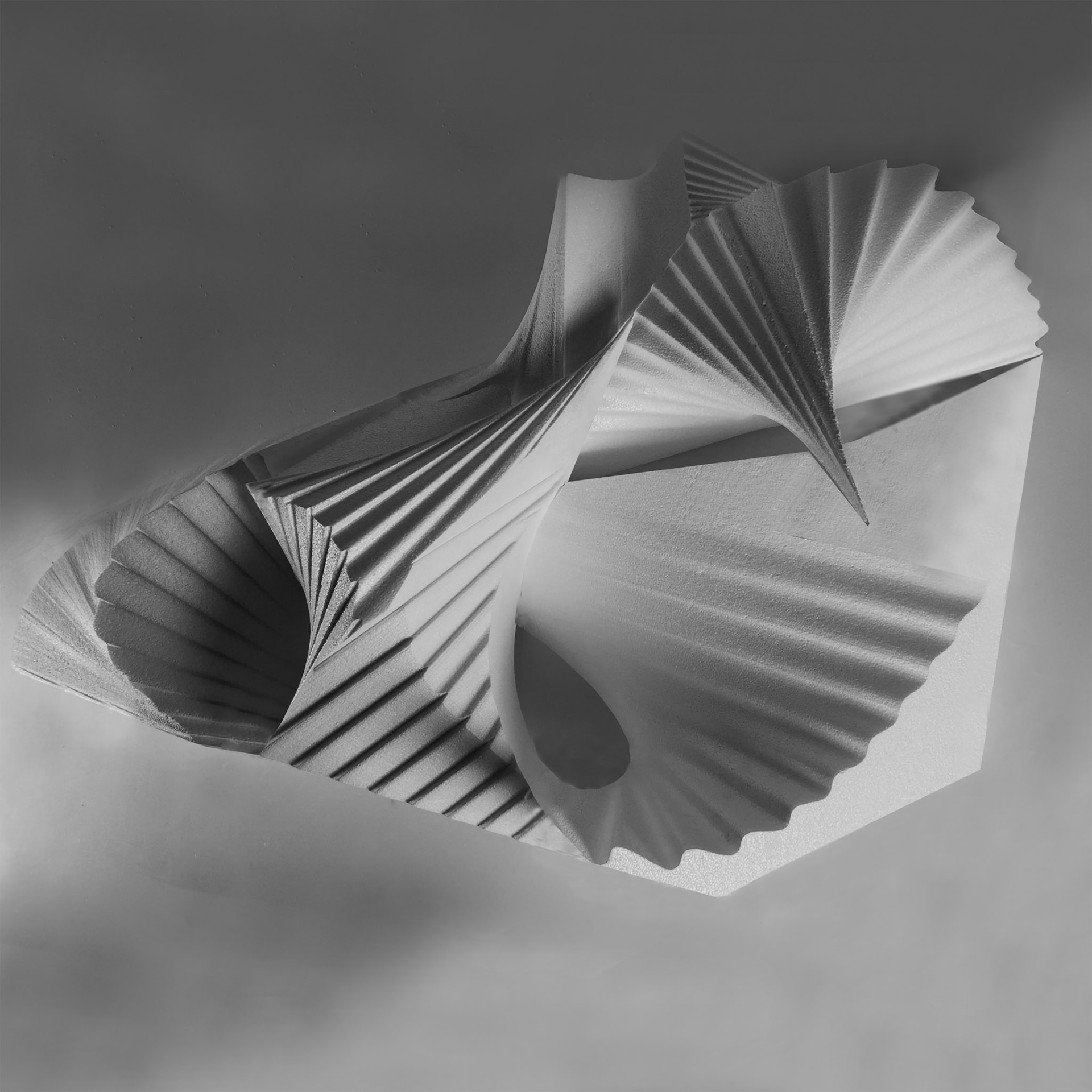

During the transposition process, the surfaces that were generated through the rails were key to transforming the “linear” hypar sculpture into a stereotomic volume. Where rails of the main sculpture were extending out and intersecting the foam block is how we started to define our limits. The proposed sculpture highlights a symbiotic relationship between the original form, it’s features and its negative spatial qualities.

The transposition process highlighted a figure ground relationship between the original sculpture and the proposed sculpture while keeping the most important characteristics created. Two rails from the original sculpture were emulated in addition to other rails that allowed the transposition of surface to volume. This constructed one half of the volumetric sculpture. The other half of the sculpture is a mirrored imitation of it, following a similar system that Gabo used in Torsion variation 3.

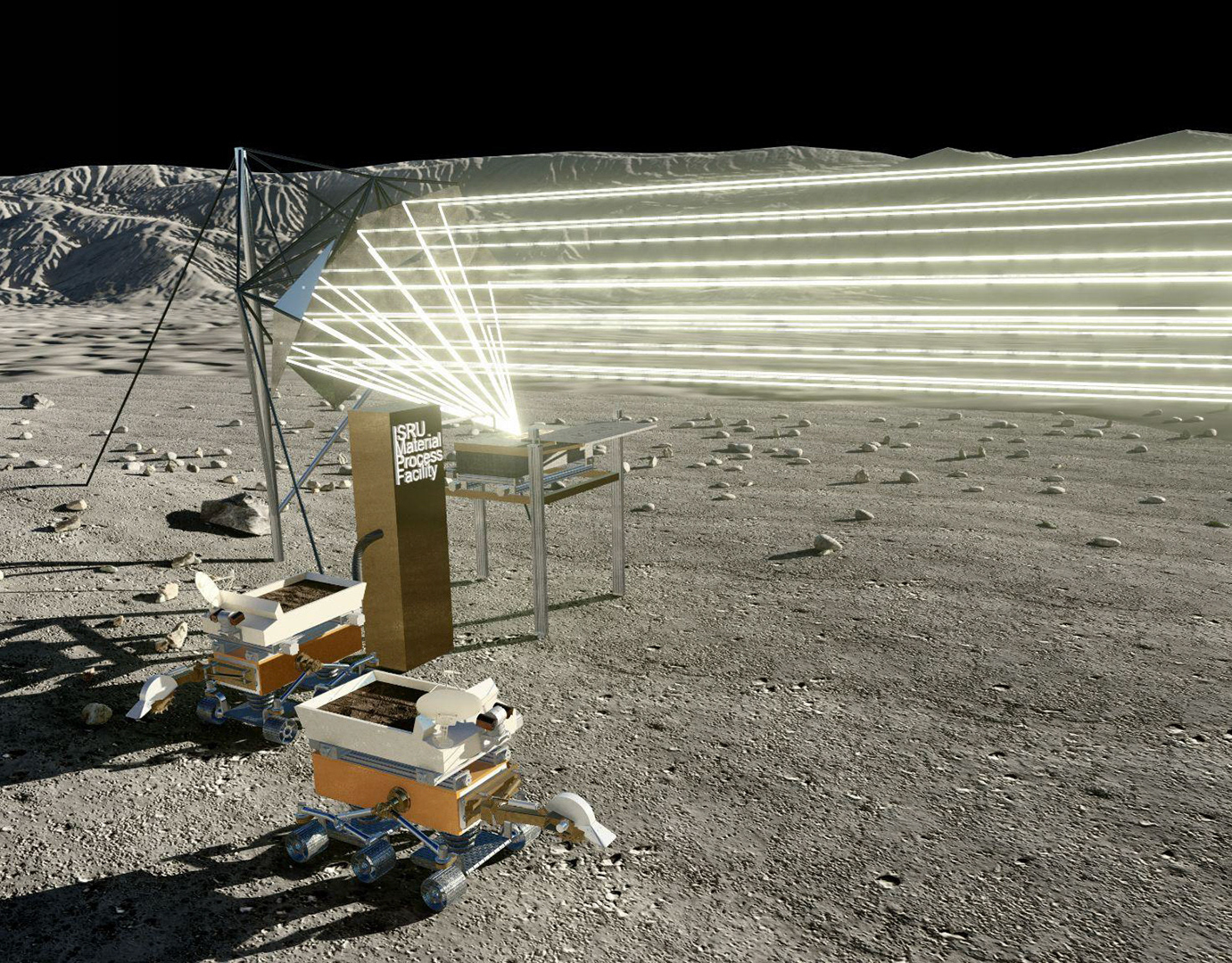

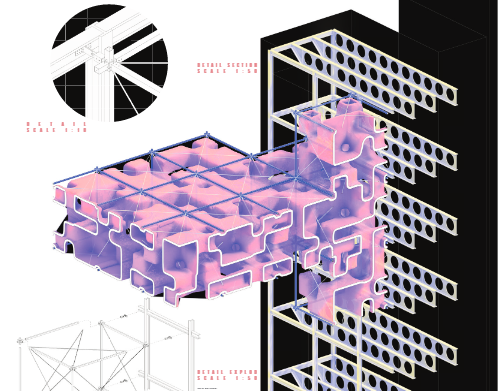

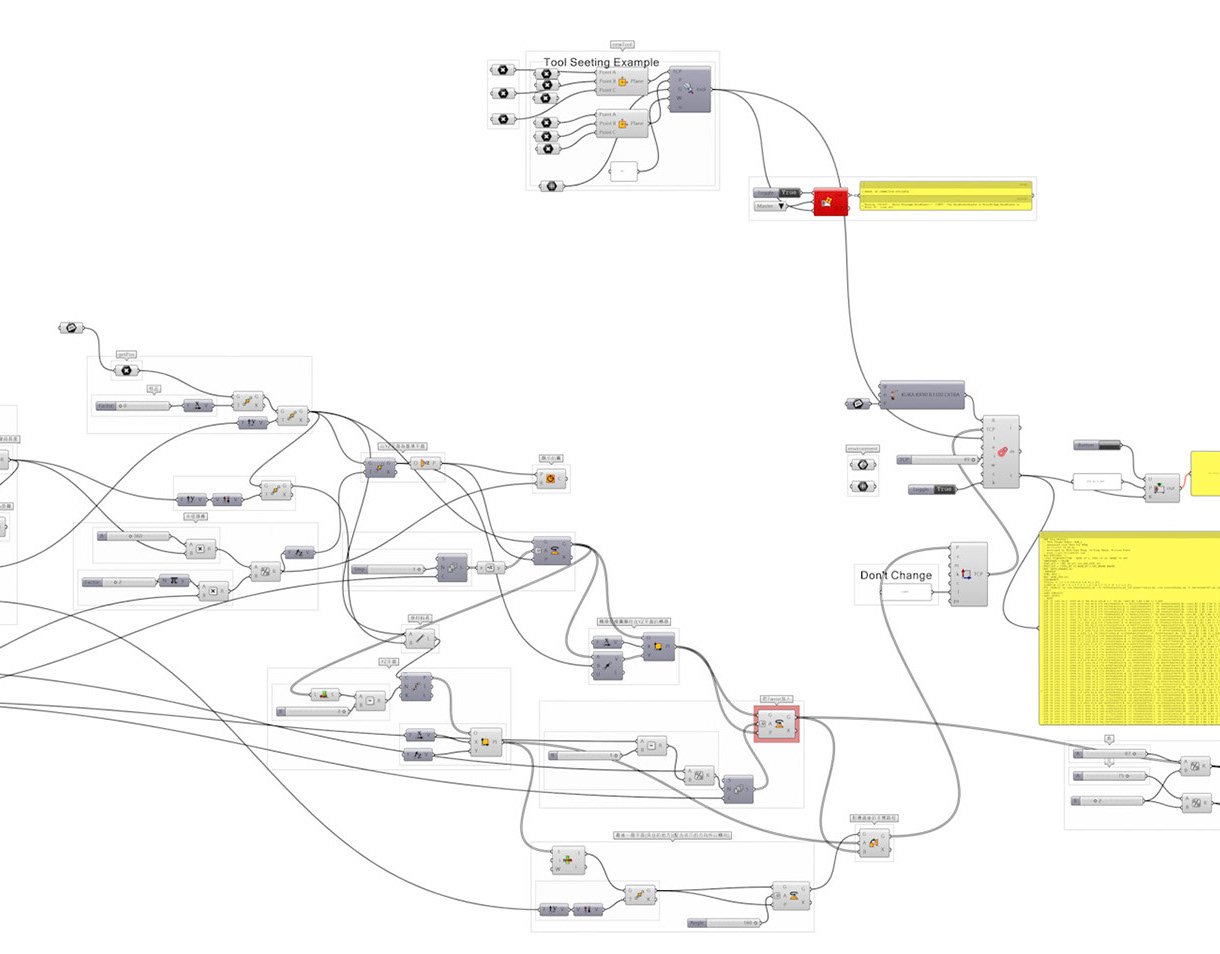

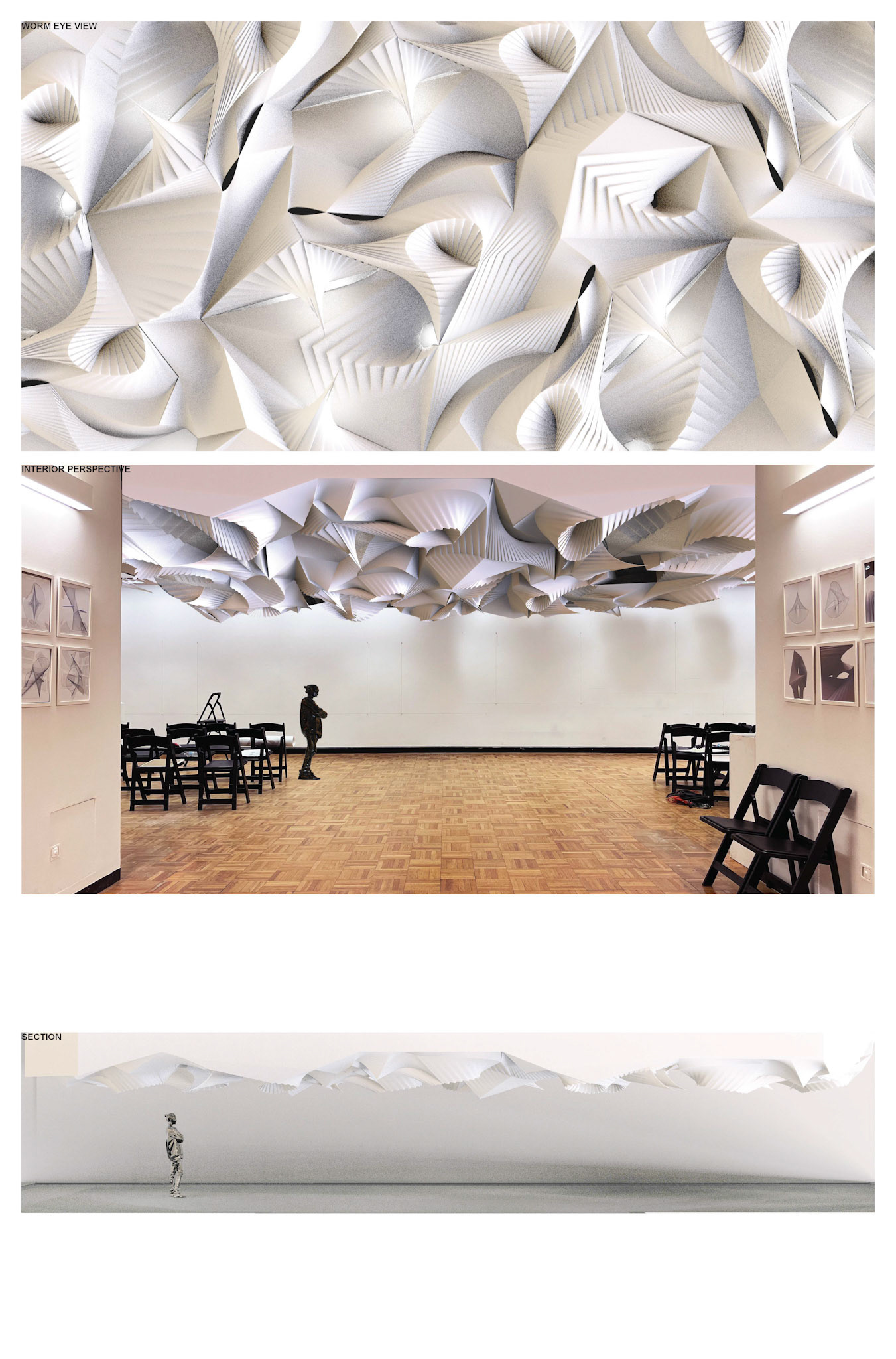

Fabrication Process Diagram

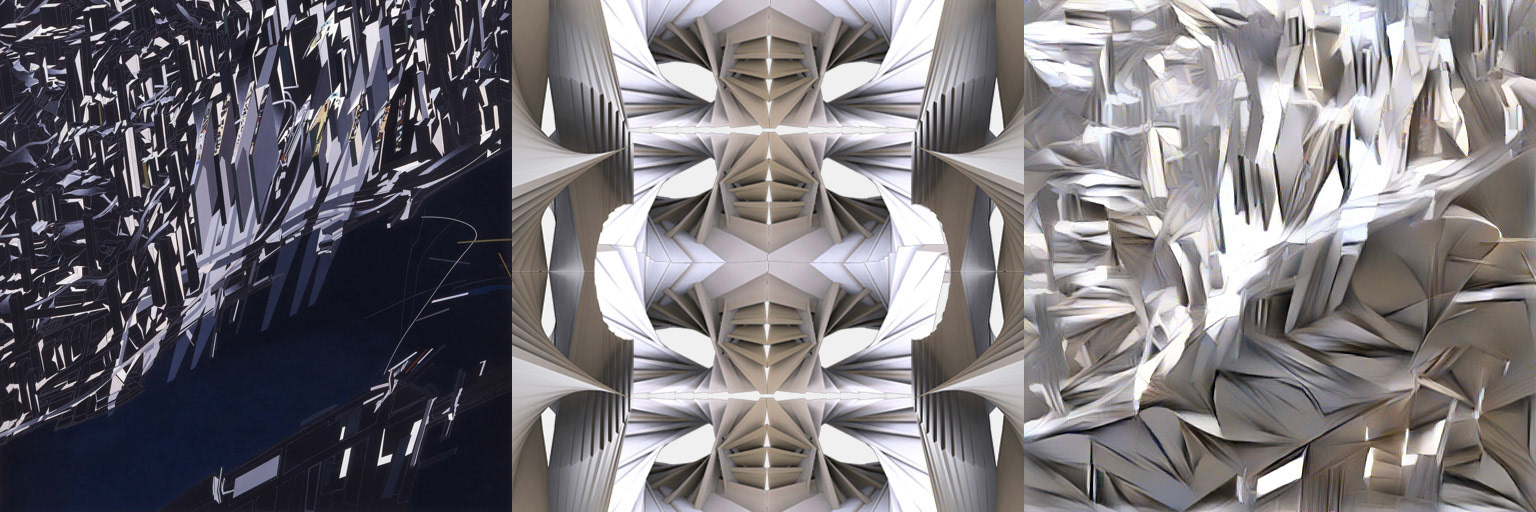

The signature module and the overall ceiling define an experimental form of fabrication. The input rails and rulings create geometries that can be seen in tectonic light tensile structures. This is however now achieving similar geometries and edges with stereotomic masses. The use of the industrial robot for fabrications often means constant experimental tests. Therefore allowing the planning of multiple choreographies that intersect together to create the fabricated pieces.

The robotic wire cutting choreography consisted of the hot wire moving across a block of foam, along a set of points in between the two set rails that create the desired ruling. Positioning of foam pieces directly related to the relative position of the input rulings, allowing for the robot to ease into the beginning points of the cuts.

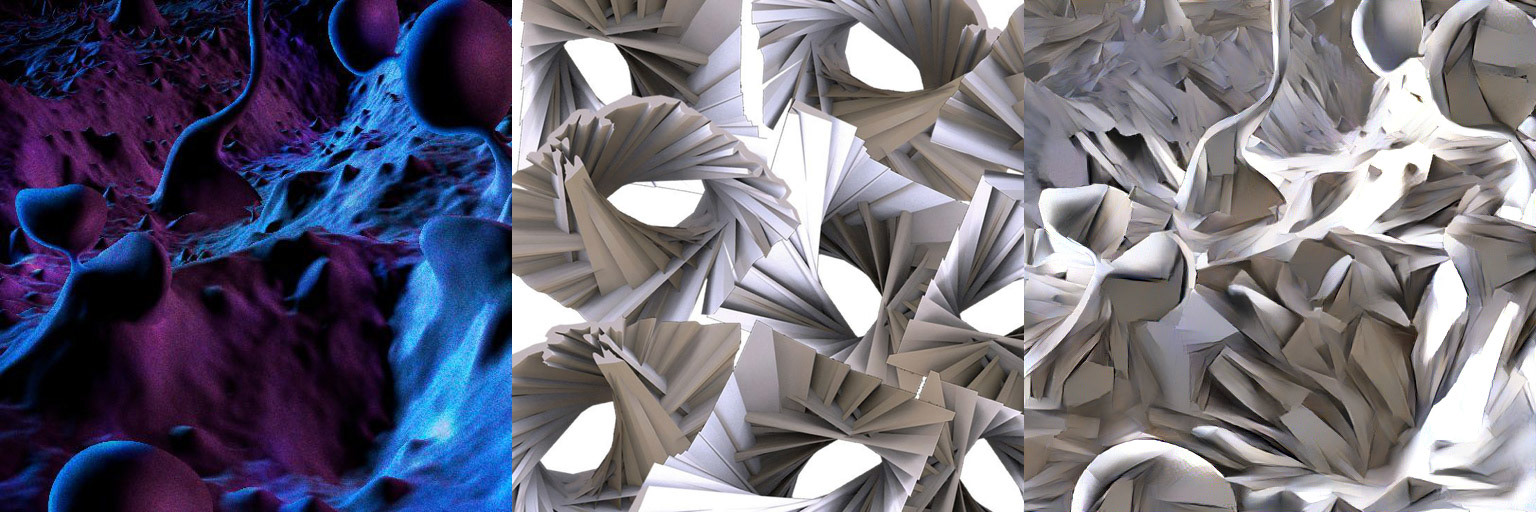

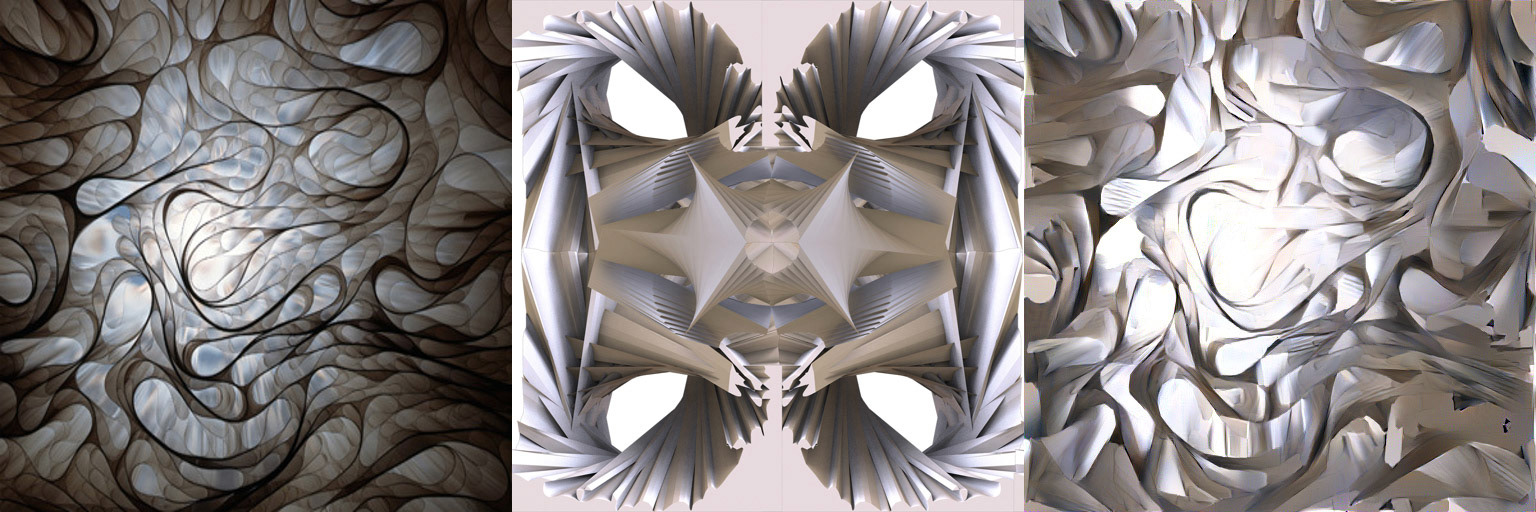

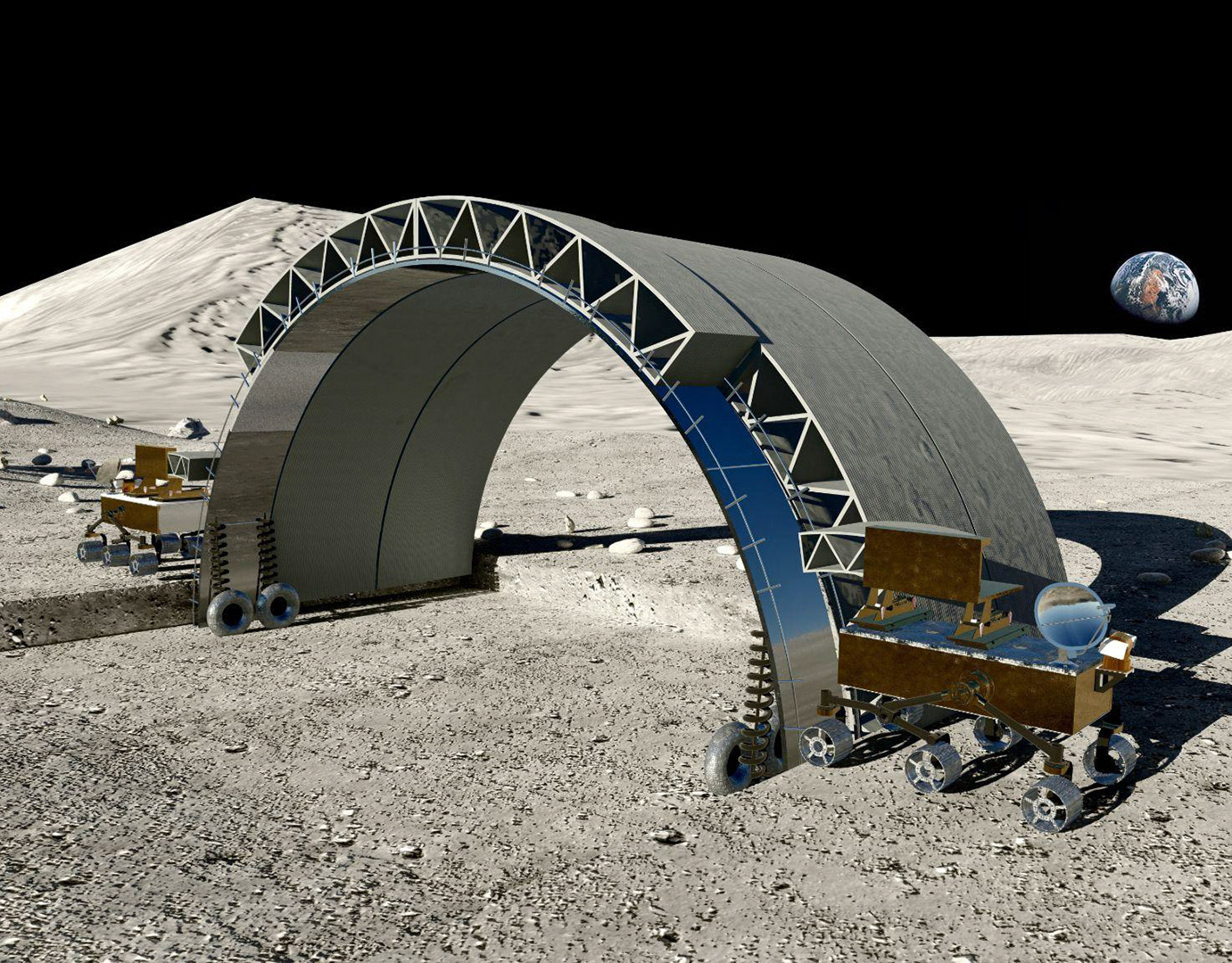

Rendering

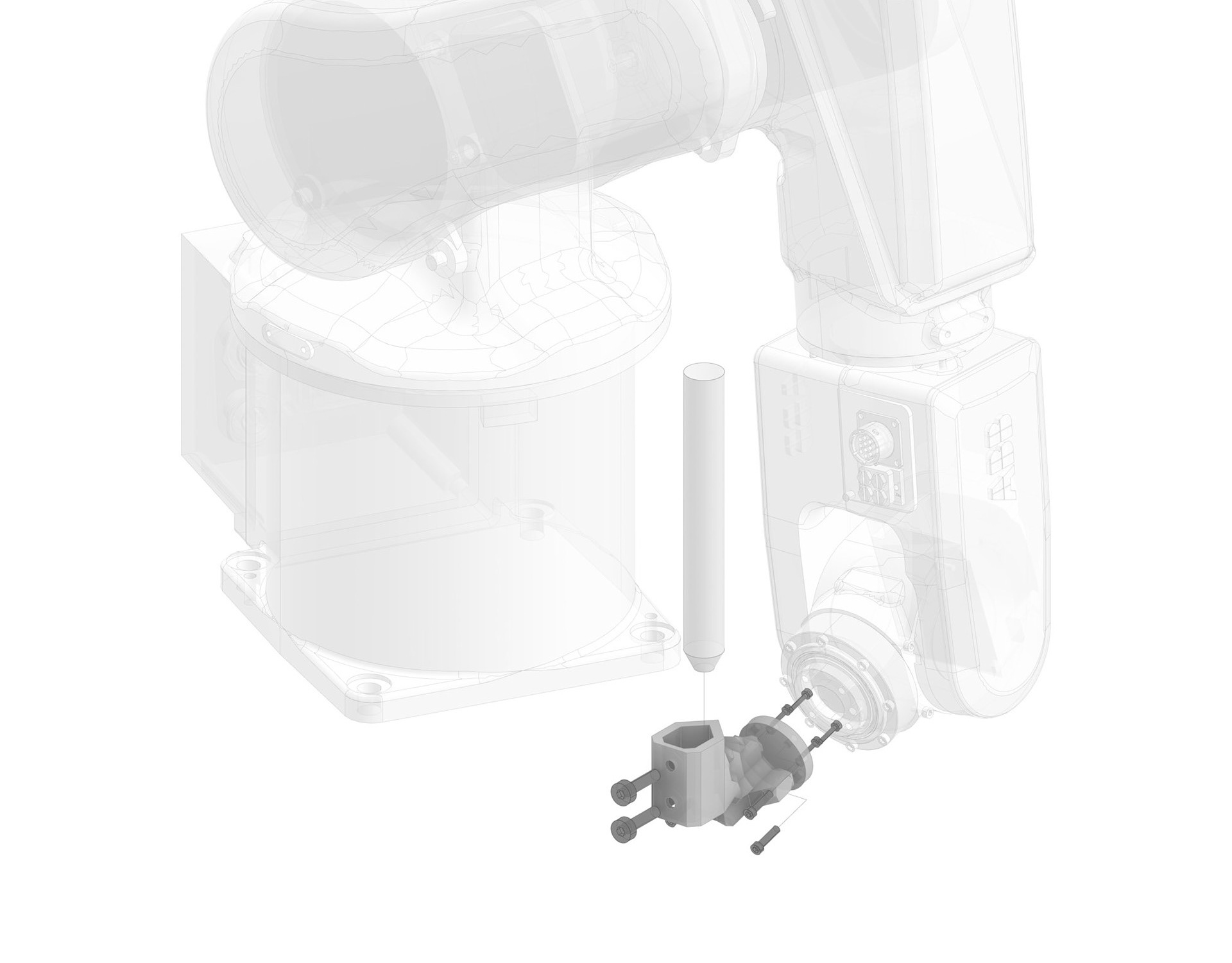

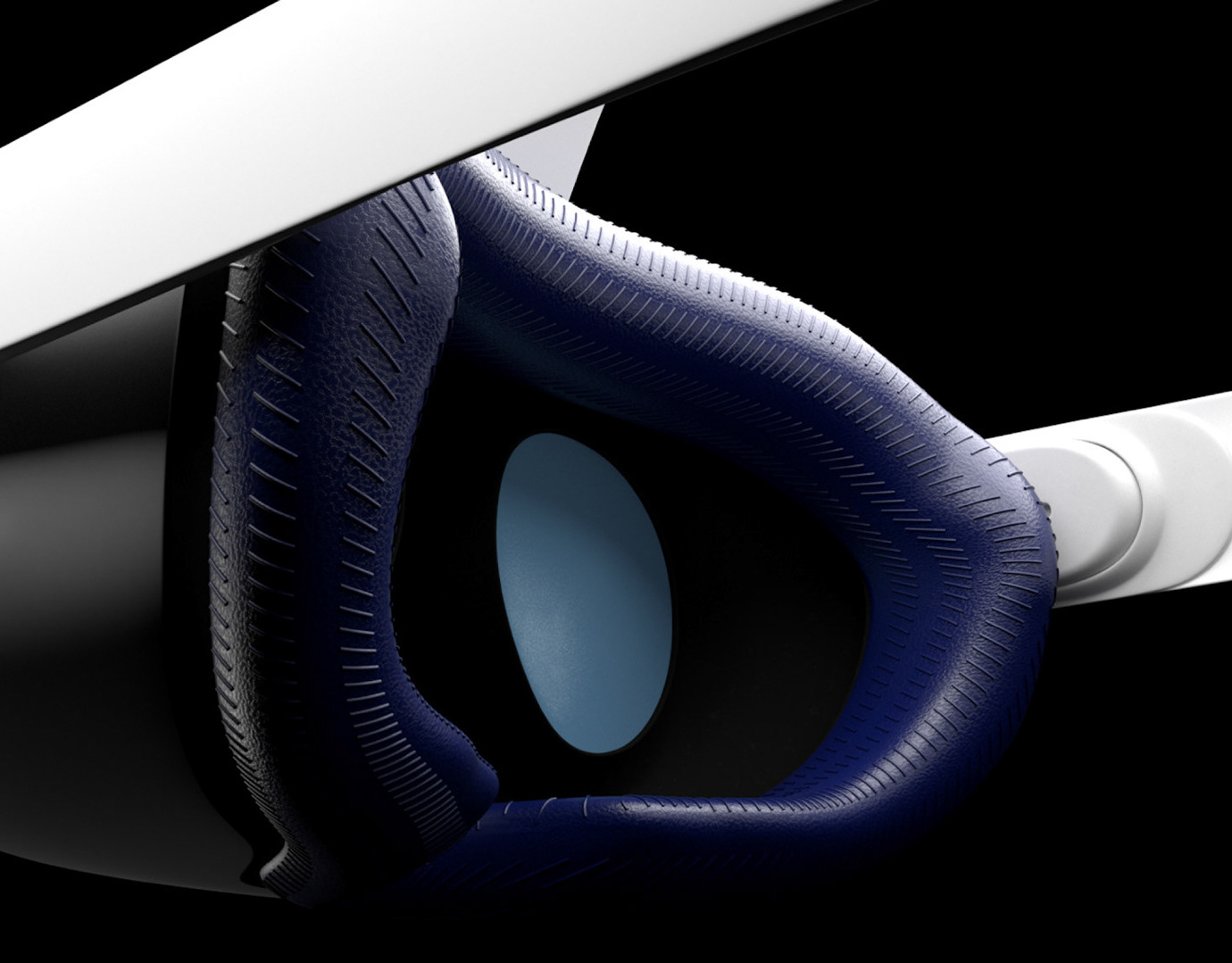

3D Printed SLA Resin

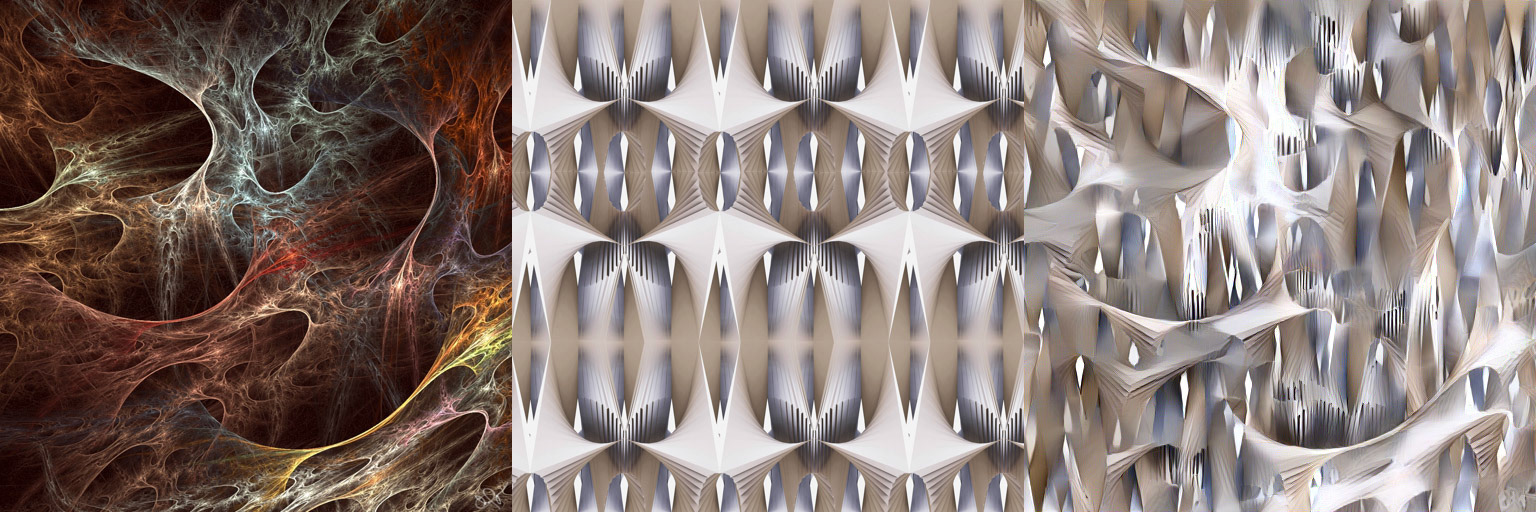

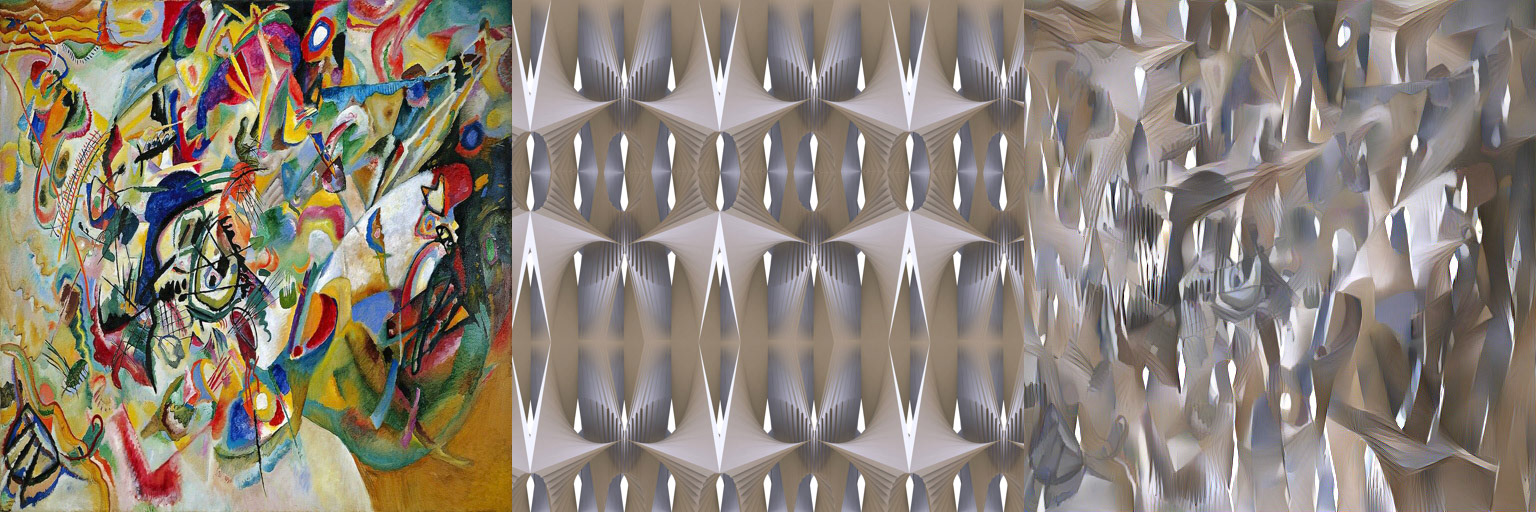

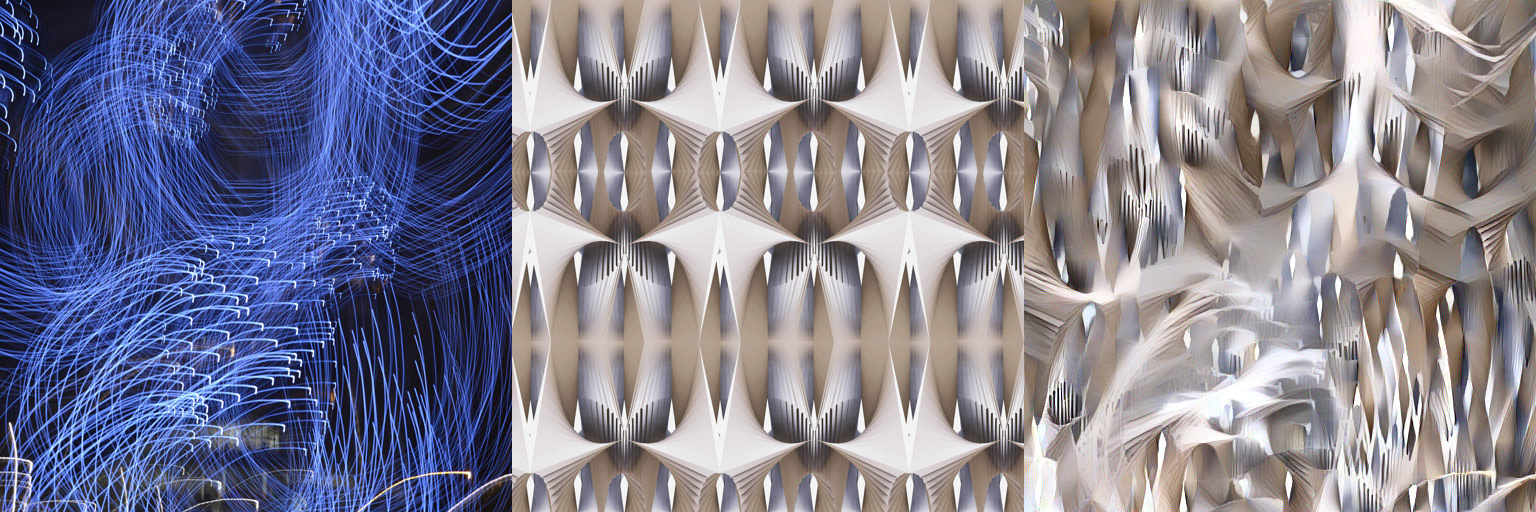

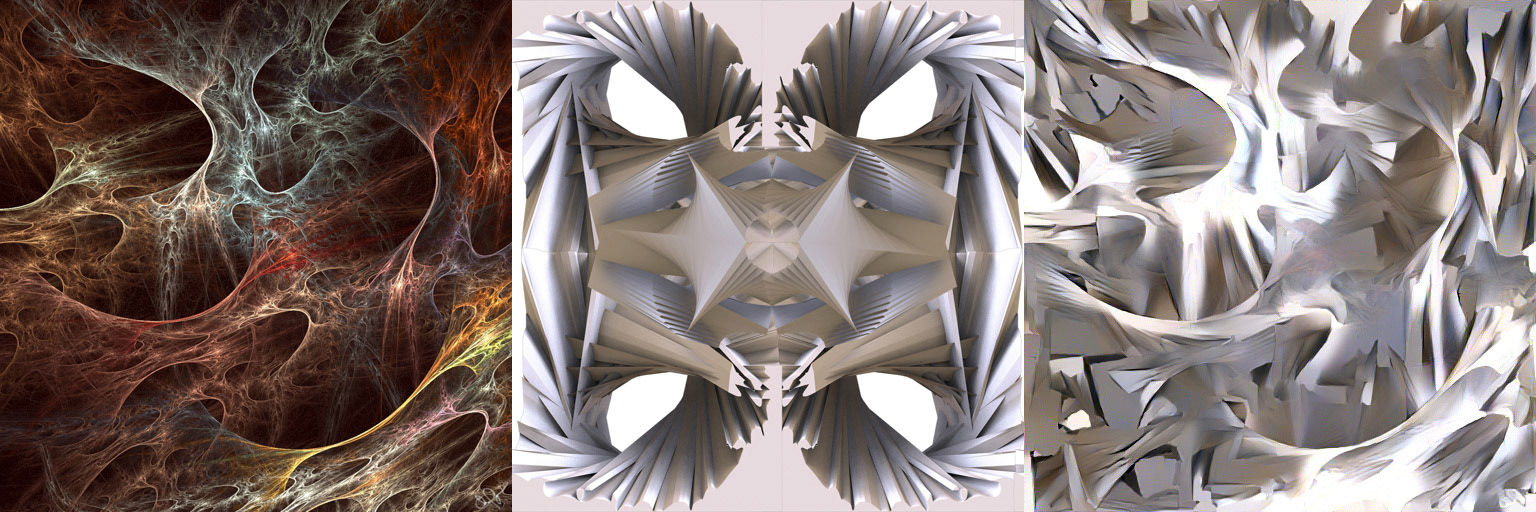

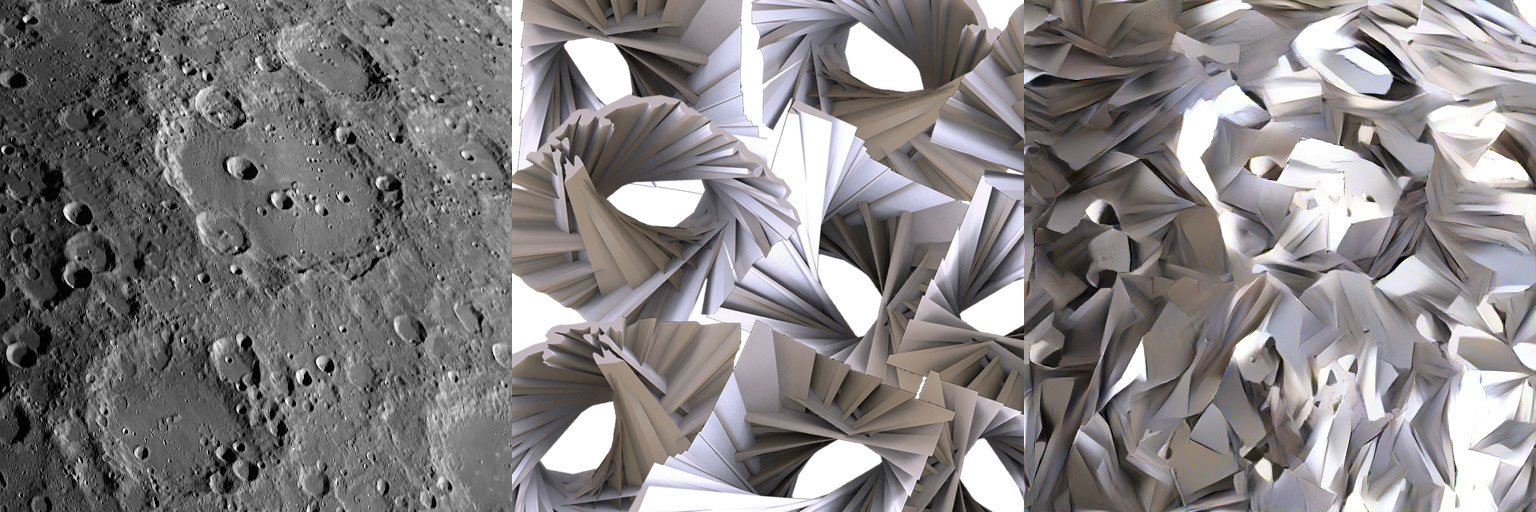

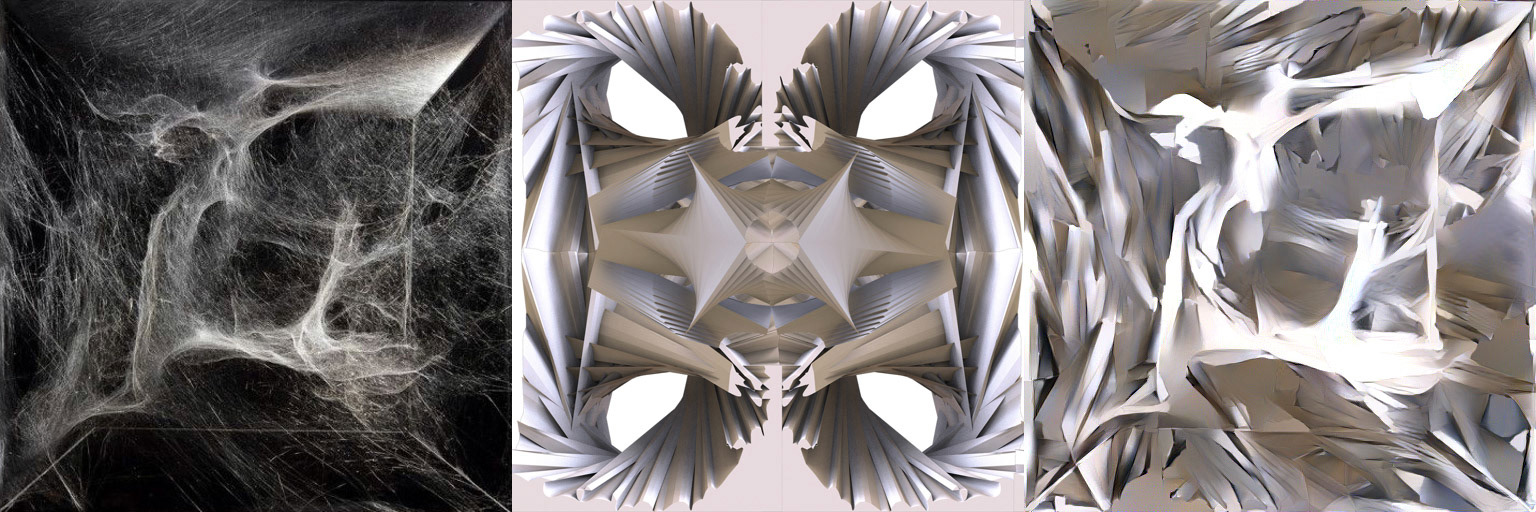

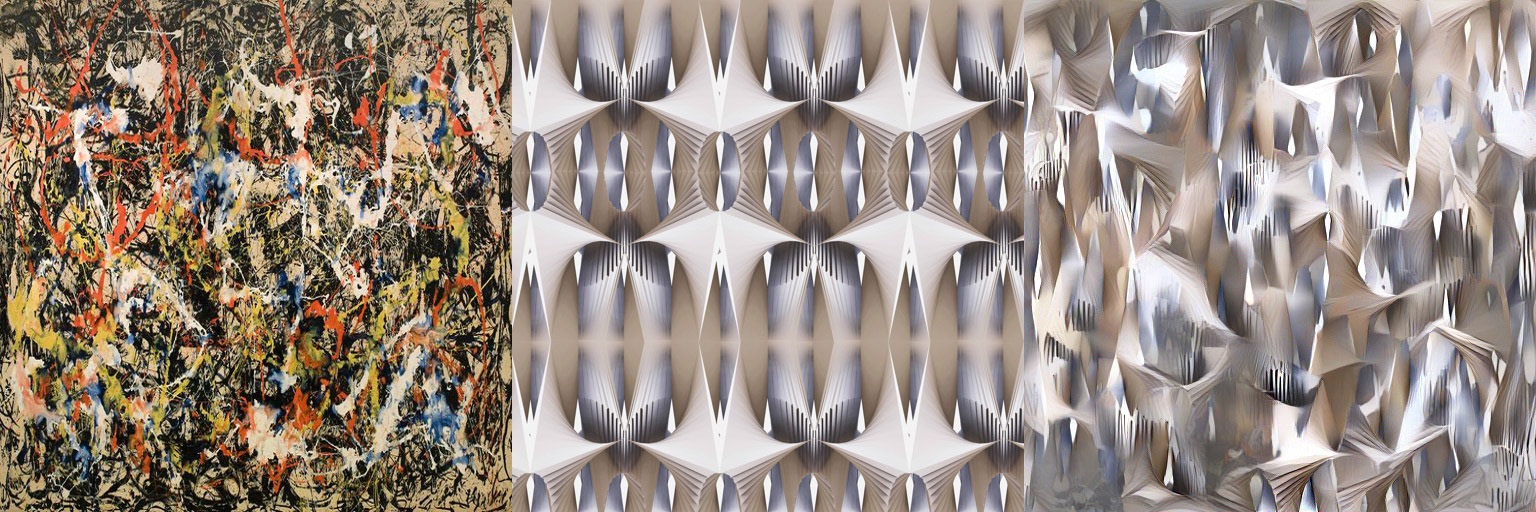

Deep learning can be considered as a part of a broader family of machine learning methods that are based on the artificial neural networks with representation learning. The technical definition of deep learning is a class of machine learning algorithms that uses multiple layers to progressively extract higher-level features from the raw input.

The model we used in this studio is convolutional neural networks, abbreviated as CNN. When the CNN is running in each level, the machine learns to transform its input data into a more complex and composite representation. In the course of the CNN process, it became clear that the machine was distinguishing the brightness comparison between the content and style image, Stitching major features into repetitive components that created a complexity through a collective system of the CNN input dataset. The output results can be considered as semi-autonomous due to its semi-unpredictable judging system.

GAN Drawing Set